Our factory mainly produces paper machinery products, including pulp boxes, watermark rollers, shaking boxes, high-speed paper machine shakers, and movable curved rollers for paper machines. The all stainless steel watermark roller produced by our factory is mainly used to improve the uniformity of the paper, and the effect is very obvious. You can also attach patterns or text to the watermark roller mesh surface. Due to complete specifications, reasonable prices, and the advantages of lightweight structure, high rigidity, good dehydration, and durability, our products have been widely used in the papermaking industry, selling well throughout the country and exported overseas.

The shaking of the long web paper machine

The purpose of shaking the chest roller and mesh of the paper machine is to overcome the phenomenon of fiber re aggregation on the mesh, reduce the directionality of fiber arrangement, and promote dehydration, in order to improve the uniformity of the paper sheet and improve its forming.

There are many factors that affect shaking, such as the influence of the slurry itself, such as the viscosity of the slurry, the thickness of the slurry layer, the length and stiffness of the fibers, the arrangement of the fibers, etc. There are also factors that affect the selection of various parameters in the shaking box, such as the frequency and amplitude of shaking. If shaken too much, it will cause the fibers that have already been deposited on the net to detach from the surface, which will affect the uniformity and even damage the forming of the paper. Therefore, the intensity of shaking should be controlled to not affect the uniformity of the paper sheet. Shaking intensity=(frequency) ² × amplitude/paper machine speed. It can be seen that factors affecting shaking intensity include shaking frequency and amplitude, as well as paper machine speed. When selecting shaking parameters, using large amplitude (10-20mm) and low vibration times (100-120 times/min) is more effective for long fiber high viscosity slurries, while using small amplitude (3-6mm) and high vibration times (300 times/min or more) is more commonly used for short fiber free slurries. If the vehicle speed increases, the vibration times should be correspondingly increased to ensure that the shaking period is less than the time the fibers pass through the shaking section, otherwise shaking will not have the desired effect.

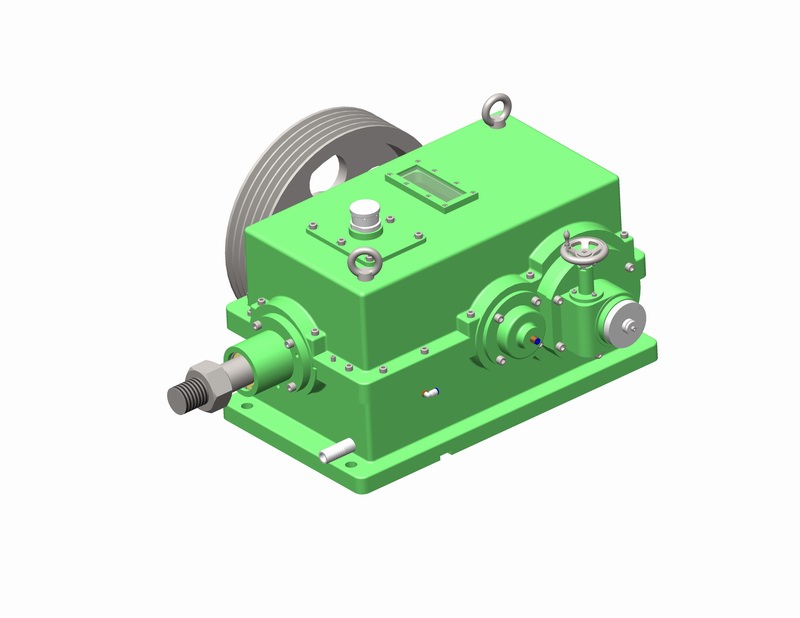

The shaking of the paper machine's chest roller and net case is achieved using an eccentric mechanism. According to factors such as the width of the paper machine, the speed of the vehicle, the structural form and installation position requirements of the shaking device, and the slurry, the form of the shaking box is selected. Currently, in China, there are low-frequency shaking boxes, medium frequency shaking boxes, and high-frequency shaking boxes distinguished by shaking frequency. Low frequency oscillation boxes such as ZT5013 (maximum inertia force 1800kgf, maximum eccentricity 10mm) and ZT5070 (maximum inertia force 3500kgf, maximum eccentricity 10mm) Suitable for narrow width and low-speed paper machines, with the increase of paper machine width and speed, as well as the emergence of screen paper machines, intermediate frequency shaking boxes and high-frequency shaking boxes (truly no recoil) suitable for paper machine operation have been produced.

Each form of shaking box has an eccentric mechanism to generate reciprocating output, an amplitude modulation mechanism to adjust amplitude, and a variable frequency motor (servo motor) to adjust vibration frequency. Due to its structural reasons, the low-frequency shaking box will generate vibrations that are transmitted to the foundation, which has certain requirements for the foundation. The higher the vibration frequency and amplitude, the greater the vibration. The intermediate frequency oscillation box has changed the structure of the low-frequency oscillation box, added weight compensation, and optimized the amplitude modulation mechanism, greatly reducing the vibration of the oscillation box. The core structure of the high-frequency shaking box consists of two sets of four identical eccentric rotors. In the motion system, these two sets of four eccentric rotors will generate an inertial force, which is transmitted to the axial chest roller through the shaking rod. Eccentric rotors are symmetrically distributed on both sides and can rotate at high speed around their axis. They turn in opposite directions, so the vertical force components cancel each other out and the horizontal force components overlap each other, causing the box supporting the rotating shaft to vibrate in the horizontal direction, that is, to produce reciprocating motion in the horizontal direction. The shaking box is connected to the chest roller through a connecting rod, forming a vibration system that generates no force or torque other than gravity, thus creating a true sense of no recoil force.

The low-frequency shaking box, ZT5013 and ZT5070 are structurally identical, but with different part sizes, resulting in different shaking inertia forces.